Tel:0086-13853037119

Tel:0086-13853037119

telephone

0086-13853037119Heze Zhenhua Machinery Manufacturing Co., Ltd.

Add.: South of Sewage Treatment Plant, East Section of Beihuan Road, Dingtao District, Heze City, Shandong Province, China

Tel.:0086-13853037119

Email:info@www.sdzhgs.com

Http://www.sdzhgs.com

0086-13853037119

0086-13853037119

Heze Zhenhua Machinery Manufacturing Co., Ltd

Heze Zhenhua Machinery Manufacturing Co., Ltd

South of Sewage Treatment Plant, East Section of Beihuan Road, Dingtao District, Heze City, Shandong Province, China

South of Sewage Treatment Plant, East Section of Beihuan Road, Dingtao District, Heze City, Shandong Province, China

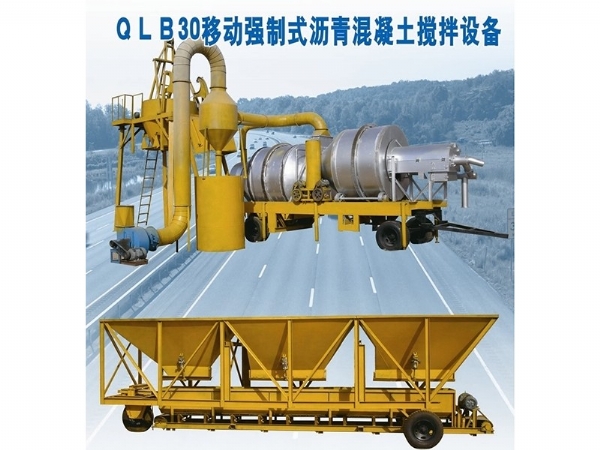

QLB-30 mobile batch asphalt mixing plant

Main parameters of the whole machine

1、Model: QLB-30;

2、Forms: mobile, easy to group 0, easy to disassemble, intermittent;

3、Rated output: 30-40t/h;

4、Stirring capacity: 1500kg/batch;

5、Operation mode: manual/automatic, full computer control;

6、Installed capacity: 100Kw

二、Main technical specifications

1、 Cold aggregate supply equipment

1.1cold hopper

A Capacity:3m3

B Quantity:3只

1、2 Aggregate conveyor belt

A Form: Three-point bracket trough frame

B Conveying capacity: 50t/h

C Belt width: 500mm

D Geared motor: BWD4-23-5.5kw

1、3 Load cell

A specification:CKNF—S--1000kg

B Quantity:4只

1、4 Pneumatic opening device

A specification:QSC100×150—2件 QSC100×200—1件

B Quantity: 3 pieces in total

2、Cold aggregate elevator

A Lifting capacity: 2t

B Lifting bucket capacity: 1500kg

C Motor power: 7.5kw

D Safety measures: equipped with upper and lower limit switches

3、 Aggregate drying system

drying cylinder

A Form: Cylindrical rotary type has positive and negative rotation

B Output: 30 tons

C Standard sizes:φ1900mm×1350 mm×12 mm

D Reducer: JZQ350 Speed ratio: 8.24

E Motor: Y160L—4 15KW

F Drive: gear drive

3、2 Mixing drum

A Form: Cylindrical rotary type has positive and negative rotation

B Output: 30 tons

C Standard sizes:φ1900mm×1350 mm×12 mm

D Reducer: JZQ350 Speed ratio: 8.24

E Motor: Y160L—4 15KW

F Drive: gear drive

3、3Drying cylinder burner (coal-fired type)

A Form: Coal burner

B Maximum energy consumption: 200kg/h (coal) coal combustion value is required to be above 5500 kcal

C Coal powder machine: FD-65 11kw

D Blower: 3kw

3.4 Drying cylinder burner (fuel-based)

A Burner ZHC60

B Power 23.5KW

4、 Asphalt supply system

A Asphalt pump: CLB-100 pump

B Asphalt weighing hopper capacity: 200 kg

C Measuring method: weighing sensor measuring CKNF—S--300

5、Powder conveying device

A Form Screw conveyor

B Capacity 15t/h

C Power 3kw

6、Air compressor

model:Y-06717 0.6m3

power:7.5kw

7、Dust removal device

A First-level cyclone dust removal

B Fan: Y5—47—9C 15kw

C Secondary water dust removal: φ1500×2000

D Filter area:3m2

E Water pump:2.2kw

8、Upgrade storage system

A Lifting bucket: capacity 2.5t

B Hoisting capacity: 2.5t

C Storage capacity: 9 cubic meters

D Power: 15kw

9、Control System

9、1 Operating room:2m×3m×2.2m

9、2 Fully automatic computer console

A Console form: piano style, fully enclosed

B Working temperature: 5℃~35℃

C Working humidity: 20%~70%

D Control system function: manual, semi-automatic, fully automatic computer control, arbitrary switching

E Main input and output functions

⑴ Enter various mixing gradations

⑵ Automatically adjust and accurately measure various gradations according to input requirements

⑶ Collect the feedback signals from various sensors, control and adjust the actions of each component in time

⑷ Display various discharge information, weighing information, discharge display, temperature display

⑸ Long-term storage of data (all production data and input formulas within five years)

⑹ Screen composition: It is represented by a color display and a dynamic simulation diagram of the whole machine, and the operation and production process are clear at a glance

9、3 Electrical wiring (configured under the guidance of the manufacturer)

A All power cables use VV cables

B Scope: Connection between control room and mixing machine

9、4 Printer function

A Print mixing date, time, finished product temperature, actual mixing gradation

B It can display, view and print daily production data, which is very convenient and intuitive to correctly understand the daily production situation.

C Working temperature: 5℃~35℃

D Working humidity: 20%~70%